Overall Air Tightness of Chemical Protective Clothing Testing

Chemical protective clothing, also known as chemical protective clothing, is protective clothing worn to protect oneself from chemical hazards or corrosive substances. Can cover the whole or most of the human body, at least can provide protection to the torso, arms or thighs. Chemical protective clothing is allowed to be a combination of multiple pieces of clothing with protective functions, and can also be used in conjunction with other protective equipment.

According to the protective performance and requirements, there are many kinds of chemical protective clothing. This article introduces the national standard requirements and test methods of airtight chemical protective clothing. Gas-tight chemical protective clothing: a single-piece chemical protective clothing with a hood, windows, and hand and foot protection. When matched with suitable respiratory protective equipment, it can protect against a higher level of toxic and harmful chemicals (gas, liquid, and solid particles) ).

Overall air tightness (air tightness) performance requirements

According to the provisions of 6.4 in the national standard GB 24539-2021, the overall air tightness test is carried out on the airtight chemical protective clothing and the airtight chemical protective clothing-ET, and the pressure drop within 4 minutes should not exceed 20% of the test pressure.

Test Methods:

Before the overall performance test of chemical protective clothing, it should be pretreated according to the standard requirements. Temperature and humidity pretreatment, wear experiment, etc. Test environment conditions: All performance tests should be carried out at (20±2)°C and relative humidity (65±4)%. Carry out in accordance with the provisions of Appendix A of the national standard GB 24539-2021.

Principle:

After inflating the airtight chemical protective clothing, after a certain period of time, the airtightness of the clothing can be determined by checking the pressure drop in the clothing.

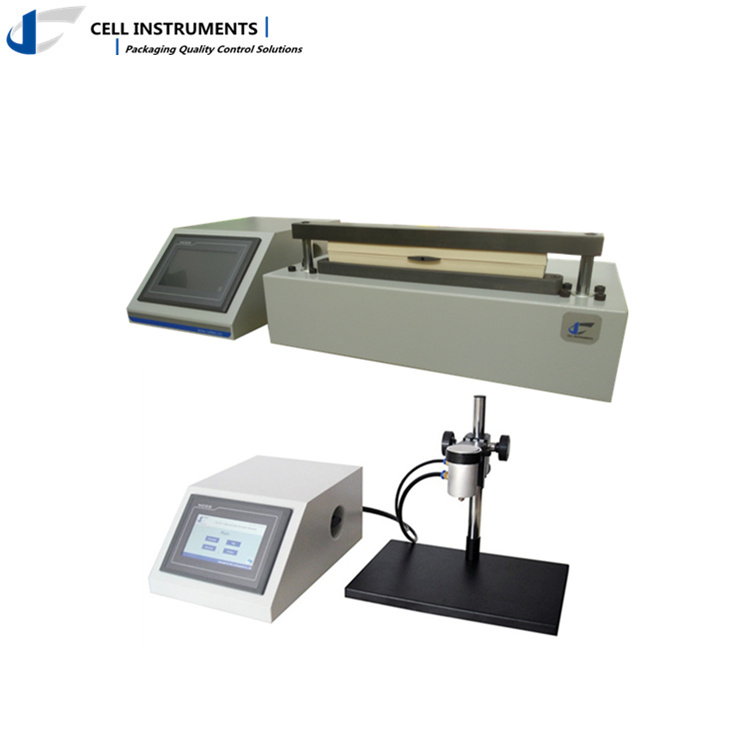

Air pump, the maximum pressure is not less than 100kPa;

Pressure gauge, accuracy 10Pa, resolution 1Pa

Timer, accuracy 0.1s

Thermometer, accuracy 1°C

Test Program:

Inflate the chemical protective clothing to the air pressure A through the air pump, and the inflation pressure A shall not be lower than 1.29kPa. Keep the stamping state for at least 1 minute to fully expand the airtight chemical protective clothing. After 4 minutes, record the final pressure C, and calculate the difference between the test pressure B and the final pressure C, that is, B-C is used as the pressure drop value, and the test pressure B should not be lower than 1.02kPa. If the pressure drop within 4 minutes is greater than 20% of B, it is judged that the airtight chemical protective clothing is unqualified and cannot be used normally. Leakage site inspection: For unqualified chemical protective clothing, the leakage site should be checked, stamped to A, and the entire protective clothing is painted with soapy water solution. The part where air bubbles appear is the leak site