Thickness Test for Lithium Batteries

The separator is an important part of the lithium battery. The separator is electronically insulating to avoid short-circuits; at the same time, it has ion conductivity to ensure the electrochemical performance of the battery. The diaphragm has a significant impact on the capacity, cycle performance, charge-discharge rate, etc. of the battery; especially has a greater impact on the safety of the battery. Therefore, the quality of the battery separator directly affects the overall performance of the battery. We can use some measurable physical and chemical indicators and electrochemical indicators to judge the impact on battery performance.

In 2018, the National Alkaline Battery Standardization Technical Committee and China Chemical and Physical Power Industry Association organized relevant enterprises to formulate the national standard "Polyolefin Separator for Lithium-ion Batteries" (standard number: GB/T36363-2018), which will be released in 2019 It will come into effect on January 1.

The label stipulates the requirements, test methods, inspection rules and other information of polyolefin separators for lithium-ion batteries. According to the standard requirements, some key test items are sorted out.

Thickness test

Thickness is the basic characteristic of all materials, and the thickness directly affects the physical properties of the overall material. Due to the porous structure of the diaphragm, if the optical non-contact measurement method is used, the data fluctuates greatly and the stability is not good.

The test is carried out by mechanical measurement method, according to the standard of "GB/T 6672 Mechanical Measurement Method for Determination of Thickness of Plastic Film and Sheet".

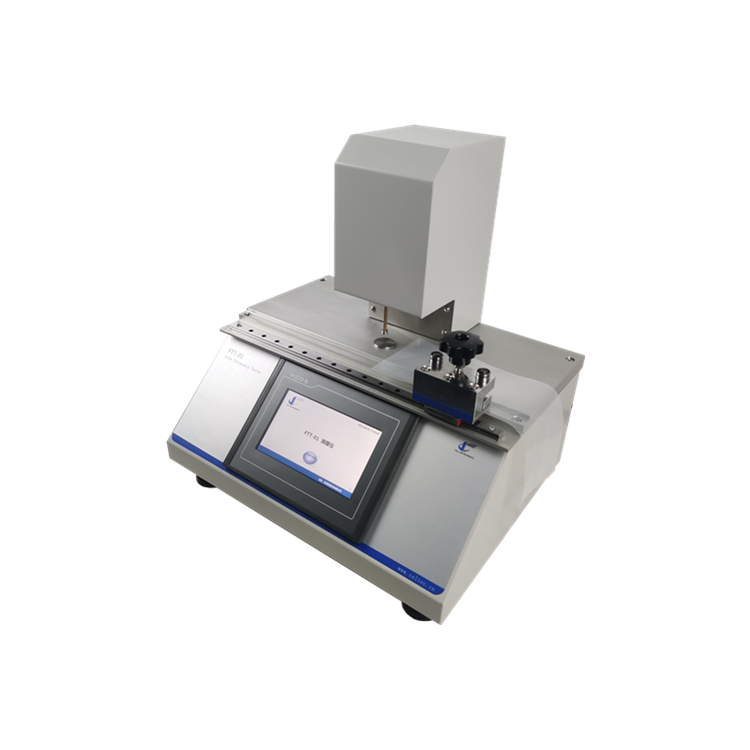

Thickness Tester FTT-01