multi-layer co-extrusion infusion

multi-layer co-extrusion infusion film bag has the following advantages:

1, good temperature resistance: can be at 121 ℃ high temperature sterilization, while maintaining low precipitation after sterilization;

2, excellent clarity: good appearance of sensory, easy appearance testing;

3, a wide range of heat sealing temperature: the film has good mechanical properties;

4, high and low temperature environment flexibility: regardless of high temperature, low temperature environment can maintain good flexibility, easy to liquid emptying, packaging, storage and transportation;

Good compatibility: it can pack many kinds of drugs.

summarizes the relevant standards and specifications of our country and the international, and the indicators for the detection and control of infusion packaging films and bags mainly include: barrier properties, mechanical properties and so on.

whether the thickness of pharmaceutical packaging material is uniform is the basis for testing its performance. Uneven thickness of packaging materials will affect the barrier, tensile strength and other properties; high-precision control of material thickness is also an important means to ensure quality and control costs.

2. instrument recommendation

The above item test fixture is used in conjunction with the medical bag tear tester to meet the needs of your company.

| Project | Details | Picture |

|

medicine bag tear tension tester MPT-01 Tensile strength and elongation at break heat-seal strength peel strength rubber plug puncture instrument retention Aluminum-plastic combination cover opening force |

Technical Features 7 inch high brightness TFT LCD touch screen for easy parameter setting and test operation The instrument meets four separate experimental items such as tension and compression test, peel strength, opening force and puncture force. precision ball screw, more accurate displacement control 1-500 mm/min test speed can be adjusted at will Professional computer software operating system, convenient for users to connect to the computer for data storage, analysis, printing limit protection and automatic protection function to ensure the operation and operation safety The instrument comes with a micro printer, which can quickly print the experimental results instrument can complete the experiment alone, through the computer software system can also complete the experiment Technical Specifications test range: 0-200N (others can be customized) measurement accuracy: ± 0.5% measuring speed: 1-500 mm/min infinitely variable speed speed accuracy: 1% error |

|

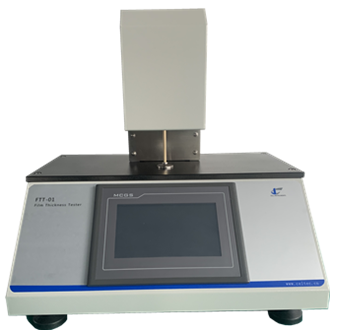

| thickness gauge FTT-01 |

Technical Features PLC control, touch screen operation In strict accordance with the standard design of the contact area and measurement pressure, while supporting a variety of non-standard customization The measuring head automatically lifts during the test, effectively avoiding system errors caused by human factors Real-time display of the maximum, minimum, average and standard deviation of the measurement results and other analysis data system supports data real-time display, automatic statistics, storage, printing and many other practical functions Technical Specifications test range: 0~2mm resolution: 0.1 μm test pressure: 17.5±1 KPa contact area: 50 mm² |

|

Fixture Introduction:

| rubber plug | rubber plug puncture force test accessory Cooperate with the medical bag tear tension tester test |

is used for the puncture resistance test of rubber plugs. |

| Aluminum-plastic combination cover opening force | Aluminum-plastic combination cover opening force test accessory (tested with medical kit tear tester) | is used for the opening force test of the aluminum-plastic composite cover. |

| Insertion Point Impermeability Tightness of injection point |

Infusion bag permeability test device | is used for testing the sealing and impermeability of the puncture point and the injection point after the infusion bag is punctured by the puncture device. |

| Suspension force | Infusion bag suspension force test device | used for infusion bag suspension resistance test. |

| opening force | pull ring opening force | Inclined 23 degree infusion bottle cap pulling device |

Theo Electromechanical is committed to the design of material testing scheme. For special invitation, please consult Jinan Theo Electromechanical Co., Ltd.

sales@celtec.cn

0531-88977153