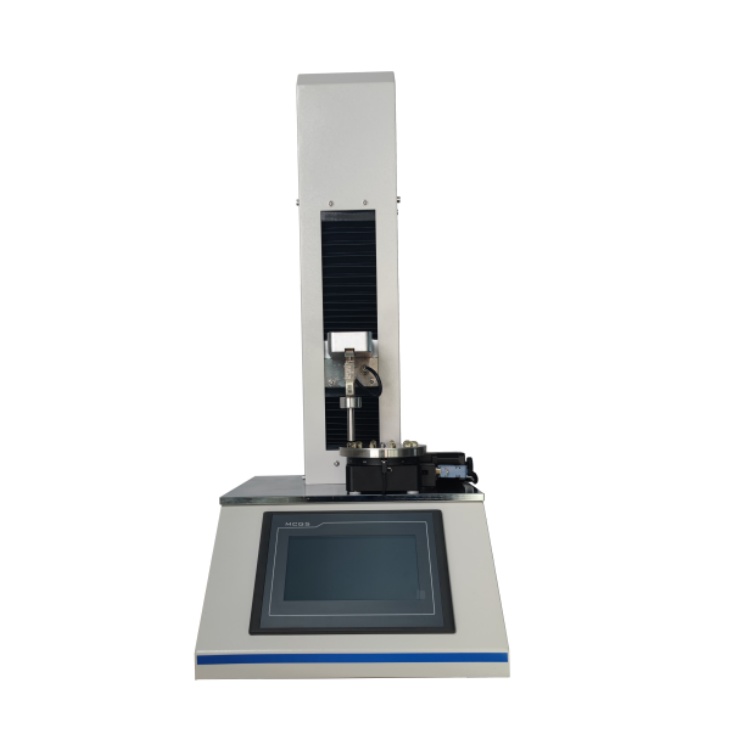

Melt Flow Rate Tester

Application

The Melt Flow Rate Tester is designed to assess the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastic materials under controlled temperature and load conditions. It employs two methods: the mass-measurement method and the displacement-measurement method. This tester is suitable for high-temperature engineering plastics such as polyethylene, polyarylsulfone, fluoroplastics, and nylon. It can also be utilized for lower melting point plastics, including polyethylene, polystyrene, polypropylene, ABS resin, and polyoxymethylene resin.

Test Principle

The determination of MFR and MVR involves extruding molten material through a specified die length and diameter from the cylinder of a plastometer at set temperature and load conditions. In the MFR measurement (Procedure A), segments of the extrudate are timed and weighed to calculate the extrusion rate in grams per 10 minutes. For MVR measurement (Procedure B), the movement of the piston over a set time or the time taken for the piston to travel a defined distance is recorded, enabling the calculation of the extrusion rate in cubic centimeters per 10 minutes. If the melt density at the testing temperature is known, MVR can be converted to MFR, or vice versa.

Standards

The Melt Flow Rate Tester complies with several standards, including ISO 1133-2, ISO 1133-1, ASTM D1238, GBT 3682.1, GBT 3682.2, GB/T18742, and JB/T 5456.

Definition

Melt Mass-Flow Rate (MFR)

MFR refers to the rate at which molten resin is extruded through a die of specific dimensions under defined temperature, load, and piston positioning conditions within the extrusion plastometer. It is measured as the mass extruded over a specified time frame and is expressed in grams per 10 minutes. In SI units, it can also be represented as decigrams per minute, where 1 g/10 min equals 1 dg/min.

Melt Volume-Flow Rate (MVR)

MVR denotes the rate at which molten resin flows through a die of particular length and diameter under specific temperature, load, and piston positioning conditions. This rate is calculated based on the volume extruded over a given time and is expressed in cubic centimeters per 10 minutes.

Understanding "Load" in MFR and MVR Testing

In the context of MFR and MVR testing, "load" refers to the total force applied, which includes the weight of the piston and any additional weights specified for the test conditions.

Common Nominal Loads

Typical nominal loads used during testing are 0.325 kg, 1.200 kg, 2.160 kg, 3.800 kg, 5.000 kg, 10.000 kg, and 21.600 kg.

-

ꄶ By Tester Name

-

Leak Tester

-

Pressure Decay/Burst Tester

-

Micro Leak Tester

-

Gross Leak Tester

-

Tensile Tester

-

Heat Seal Tester

-

Coefficient of Friction Tester

-

Falling Dart Impact Tester

-

Falling Ball Impact Tester

-

Pendulum Impact Tester

-

Hot Tack Tester

-

Shrink Tester

-

Cling Peel Force Tester

-

Thickness Tester

-

Flex Durability Tester

-

Elmendorf Tear Tester

-

Peel Test Stand

-

Test Stand

-

Impact Tester

-

Carbonation Tester

-

Torque Tester

-

Bottle Tester

-

Lid Film Peeling Tester

-

Box Compression Tester/BCT Tester

-

Ink Rub Tester

-

Mullen Bursting Tester

-

Plybond Tester

-

Stiffness Tester

-

Folding Endurance Tester

-

Beating Freeness Tester

-

COBB Tester

-

Concora Medium Fluter

-

Puncture Tester

-

Crush Tester

-

Ink Rub Tester

-

Paper Core Compression Tester

-

Paper Dirt Tester

-

Board Thickness Tester

-

Paper Thickness Tester

-

Softness Tester

-

Short Span Compression Tester

-

Paper Tear Tester

-

Smoothness Tester

-

Air Permeance Tester

-

Paper Tensile Tester

-

Valley Beater

-

Bending Stiffness Tester

-

Taber Stiffness Tester

-

Ampoule Breaking Tester

-

Softgel Hardness Tester

-

Pharm and Medical Packaging Tester

-

Glass Grain Sampling Machine

-

Cap Opening Force Tester

-

Medical Syringe Tester

-

Puncture Tester

-

Drawing Volume Tester

-

Tablet Hardness Tester

-

Motorized Torque Tester

-

Package Compression Tester

-

Verticality Tester

-

Bottle Thickness Tester

-

Top Load Tester

-

Vibration Test Machine

-

Ball Tack Tester

-

High Speed Unwinding Force Tester

-

Loop Tack Tester

-

Tape Shear Adhesion Tester

-

Cleaning Efficacy Tester

-

Mop Cloth Coefficient of Friction Tester

-

Hot Air Thermal Shrinkage Tester

-

Mop Friction Force Tester

-

Charpy and lzod lmpact Tester

-

Melt Flow Rate Tester

-

Stylus Pen Sliding and COF Tester

-

Pendulum Hammer Striking Tester

-

Texture Analyzer

-

Gel Strength Tester

-

Tensile Tester

-

-

ꄶ By Test Type

-

ꄶ By Test Material

-

ꄶ By Industry

-

ꄶ By Test Standard

-

ꁇ GB Standard

-

GB 8808

-

GB 7000.1

-

GB 10006

-

GB 15171

-

GB/T 10792

-

GB/T 1040

-

GB/T 9639

-

GB/T 8809

-

GB/T 13519

-

GB/T 6672

-

GB/T 451

-

GB/T 6547

-

GB/T 10440

-

GB/T 18454

-

GB/T 19741

-

GB/T 17447

-

GB/T 17876

-

GB/T 10004

-

GB/T 40266

-

GB/T 2637

-

GB/T 12416.2

-

GB/T 6582

-

GB/T 15267

-

GB/T 16578.2

-

GB/T 55

-

GB/T 2423

-

GB/T 20138

-

GB/T17876

-

GB/T 8942

-

GB/T 2679.10

-

GB/T12914

-

GB/T 24328.3

-

GB/T 24328.4

-

GB/T 24328.5

-

GB/T24325

-

GB/T 2679.3

-

GB/T 22364

-

GB/T 2679.8

-

GB/T 6546

-

GB/T 6548

-

GB/T 22874

-

GB 2679.6

-

GB/T 4857.3

-

GB/T 4857.4

-

GB 4857.7

-

GB/T 4852

-

GT/T 4851

-

GB/T 3682.1

-

GB/T 3682.2

-

GB/T18742

-

-

ꁇ ISO Standard

-

ISO 8295

-

ISO 11607

-

ISO 7765

-

ISO 4593

-

ISO 3034

-

ISO 534

-

ISO 719 ISO 720

-

ISO 12625

-

ISO 6383

-

ISO 1974

-

ISO 16260

-

ISO 9895

-

ISO 1924-1

-

ISO 1924-2

-

ISO 1924-3

-

ISO 12625-4

-

ISO 12625-5

-

ISO 5264

-

ISO 2493-2

-

ISO 12192

-

ISO 3037

-

ISO 3035

-

ISO 16945

-

ISO 2234

-

ISO 12048

-

ISO 2874

-

ISO 2872

-

ISO 8113

-

ISO 2247

-

ISO 1133-2

-

ISO 1133-1

-

ISO 8510-2

-

ISO 14616

-

ISO 37

-

-

ꁇ ASTM Standard

-

ASTM D202

-

ASTM D882

-

ASTM D3078

-

ASTM D4918

-

ASTM F1140

-

ASTM F2029

-

ASTM F2054

-

ASTM D1709

-

ASTM D3420

-

ASTM D2732

-

ASTM D374

-

ASTM D1777

-

ASTM F392

-

ASTM D 2063

-

ASTM D3198

-

ASTM D3474

-

ASTM D5264

-

ASTM D5458

-

ASTM D1894

-

ASTM F2338

-

ASTM D1424

-

ASTM D689

-

ASTM F2096

-

ASTM 0000

-

ASTM D2923

-

ASTM D6828

-

ASTM D5342

-

ASTM D5650

-

ASTM D3301

-

ISO 7263-1

-

ASTM D642

-

ASTM D4169

-

ASTM D2659

-

ASTM D4577

-

ASTM D999

-

ASTM D3121

-

ASTM D1000

-

ASTM D3654

-

ASTM D1238

-

ASTM D4917

-

ASTM D3330

-

ASTM F1921

-

ASTM D1922

-

ASTM D638

-

ASTM E4

-

ASTM F904

-

ASTM F88

-

ASTM D1938

-

-

ꁇ YBB Standard

-

ꁇ QB/T Standard

-

ꁇ YY/T Standard

-

ꁇ BB Standard

-

ꁇ TAPPI Standard

-

ꁇ IEC Standard

-

ꁇ JIS Standard

-

ꁇ EN DIN Standard

-

ꁇ PSTC Standard

-

FINAT Standard

-

ꁇ BS Standard

-

ꁇ NF Standard

-