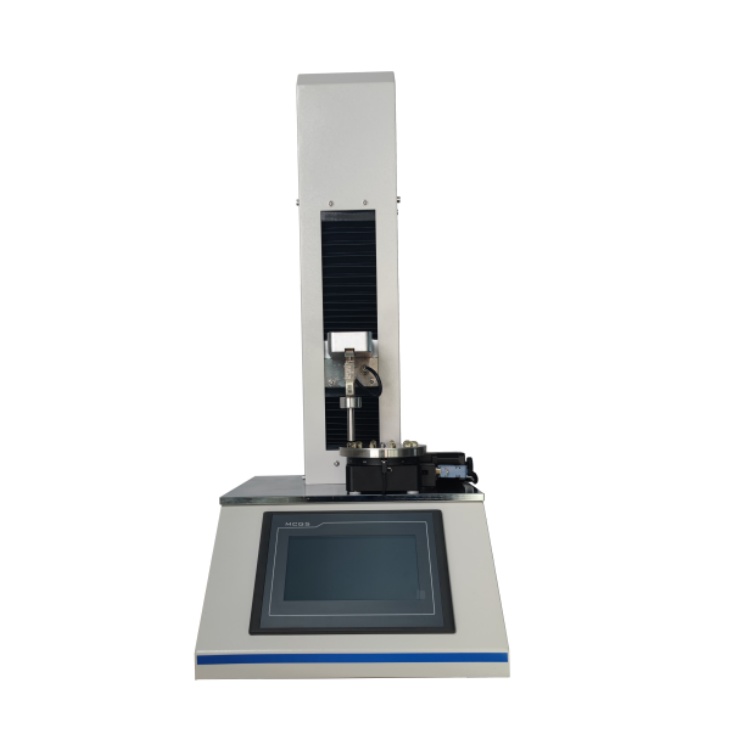

MPT-01 Medical Packaging Tester

The MPT-01 Medical Packaging Tester is an advanced and specialized instrument meticulously designed for the medical industry to assess the mechanical properties of various packaging materials used in medical devices and pharmaceutical products. This versatile tester is capable of performing a comprehensive range of tests, including tensile, compression, tear, opening force, penetration, breaking strength, and pull tests. These tests are crucial for evaluating materials such as polymers, bags, ampoules, rubber stoppers, syringes, and needles. By utilizing the Medical Packaging Tester, manufacturers can ensure their packaging materials meet the stringent quality control and regulatory standards essential for medical device and pharmaceutical packaging.

The Medical Packaging Tester is essential in conducting numerous critical tests and measurements to guarantee the quality and safety of packaging materials and components in the medical industry. The diverse range of tests performed by this tester includes:

- Penetration Test of Rubber Stoppers in antibiotic bottles and hypodermic needles, ensuring the integrity of seals.

- Fracture Strength Test of Ampoule Bottles to determine the breaking point under stress.

- Leak Test of Plastic Packages under External Pressure to verify the airtightness and prevent contamination.

- Connection Force Testing between Hypodermic Needle and Needle Hub/Cap to ensure secure attachments.

- Bottle Stiffness Test for evaluating the rigidity and durability of packaging bottles.

- Bottle Lid Puncture Test with Animated Finger to simulate real-world usage conditions.

- Sliding Resistance Test of Pistons to assess the smoothness and reliability of piston movements.

Technical Features

-

The Medical Packaging Tester boasts several advanced technical features that ensure high performance, reliability, and user-friendly operation:

- Industrial PLC Control: Utilizes a programmable logic controller at an industrial level, providing stable and reliable operation.

- HMI Touch Screen: Features a Human-Machine Interface touch screen for intuitive and easy operation.

- Precision Ball Lead Screw Mechanism: Guarantees precise and consistent speed and displacement control, essential for accurate testing results.

- Customized Programs: Capability to design and implement customized testing programs tailored to specific applications.

- Adjustable Test Speed: Offers a wide range of adjustable test speeds to accommodate various testing requirements.

- Dual Movement Direction Tests: Provides flexibility in conducting tests in both pulling and compression directions.

- Multiple Fixtures Available: A variety of fixtures can be provided on demand to suit different testing needs.

- Limit Protection and Automatic Returning: Ensures safety and efficiency in operation.

- Microprinter Integration: Enables immediate printing of test results for record-keeping and analysis.

- Professional Software and RS232 Port (optional): Facilitates advanced data management and connectivity.

| Item | Parameters |

| Test Range | 500N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Control | PLC and human machine interface |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

| Chamber Acrylic | 34*20*15cm LWH |

| Compressed Air | 0.6MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

-

ꄶ By Tester Name

-

Leak Tester

-

Pressure Decay/Burst Tester

-

Micro Leak Tester

-

Gross Leak Tester

-

Tensile Tester

-

Heat Seal Tester

-

Coefficient of Friction Tester

-

Falling Dart Impact Tester

-

Falling Ball Impact Tester

-

Pendulum Impact Tester

-

Hot Tack Tester

-

Shrink Tester

-

Cling Peel Force Tester

-

Thickness Tester

-

Flex Durability Tester

-

Elmendorf Tear Tester

-

Peel Test Stand

-

Test Stand

-

Impact Tester

-

Carbonation Tester

-

Torque Tester

-

Bottle Tester

-

Lid Film Peeling Tester

-

Box Compression Tester/BCT Tester

-

Ink Rub Tester

-

Mullen Bursting Tester

-

Plybond Tester

-

Stiffness Tester

-

Folding Endurance Tester

-

Beating Freeness Tester

-

COBB Tester

-

Concora Medium Fluter

-

Puncture Tester

-

Crush Tester

-

Ink Rub Tester

-

Paper Core Compression Tester

-

Paper Dirt Tester

-

Board Thickness Tester

-

Paper Thickness Tester

-

Softness Tester

-

Short Span Compression Tester

-

Paper Tear Tester

-

Smoothness Tester

-

Air Permeance Tester

-

Paper Tensile Tester

-

Valley Beater

-

Bending Stiffness Tester

-

Taber Stiffness Tester

-

Ampoule Breaking Tester

-

Softgel Hardness Tester

-

Pharm and Medical Packaging Tester

-

Glass Grain Sampling Machine

-

Cap Opening Force Tester

-

Medical Syringe Tester

-

Puncture Tester

-

Drawing Volume Tester

-

Tablet Hardness Tester

-

Motorized Torque Tester

-

Package Compression Tester

-

Verticality Tester

-

Bottle Thickness Tester

-

Top Load Tester

-

Vibration Test Machine

-

Ball Tack Tester

-

High Speed Unwinding Force Tester

-

Loop Tack Tester

-

Tape Shear Adhesion Tester

-

Cleaning Efficacy Tester

-

Mop Cloth Coefficient of Friction Tester

-

Hot Air Thermal Shrinkage Tester

-

Mop Friction Force Tester

-

Charpy and lzod lmpact Tester

-

Melt Flow Rate Tester

-

Stylus Pen Sliding and COF Tester

-

Pendulum Hammer Striking Tester

-

Texture Analyzer

-

Gel Strength Tester

-

Tensile Tester

-

-

ꄶ By Test Type

-

ꄶ By Test Material

-

ꄶ By Industry

-

ꄶ By Test Standard

-

ꁇ GB Standard

-

GB 8808

-

GB 7000.1

-

GB 10006

-

GB 15171

-

GB/T 10792

-

GB/T 1040

-

GB/T 9639

-

GB/T 8809

-

GB/T 13519

-

GB/T 6672

-

GB/T 451

-

GB/T 6547

-

GB/T 10440

-

GB/T 18454

-

GB/T 19741

-

GB/T 17447

-

GB/T 17876

-

GB/T 10004

-

GB/T 40266

-

GB/T 2637

-

GB/T 12416.2

-

GB/T 6582

-

GB/T 15267

-

GB/T 16578.2

-

GB/T 55

-

GB/T 2423

-

GB/T 20138

-

GB/T17876

-

GB/T 8942

-

GB/T 2679.10

-

GB/T12914

-

GB/T 24328.3

-

GB/T 24328.4

-

GB/T 24328.5

-

GB/T24325

-

GB/T 2679.3

-

GB/T 22364

-

GB/T 2679.8

-

GB/T 6546

-

GB/T 6548

-

GB/T 22874

-

GB 2679.6

-

GB/T 4857.3

-

GB/T 4857.4

-

GB 4857.7

-

GB/T 4852

-

GT/T 4851

-

GB/T 3682.1

-

GB/T 3682.2

-

GB/T18742

-

-

ꁇ ISO Standard

-

ISO 8295

-

ISO 11607

-

ISO 7765

-

ISO 4593

-

ISO 3034

-

ISO 534

-

ISO 719 ISO 720

-

ISO 12625

-

ISO 6383

-

ISO 1974

-

ISO 16260

-

ISO 9895

-

ISO 1924-1

-

ISO 1924-2

-

ISO 1924-3

-

ISO 12625-4

-

ISO 12625-5

-

ISO 5264

-

ISO 2493-2

-

ISO 12192

-

ISO 3037

-

ISO 3035

-

ISO 16945

-

ISO 2234

-

ISO 12048

-

ISO 2874

-

ISO 2872

-

ISO 8113

-

ISO 2247

-

ISO 1133-2

-

ISO 1133-1

-

ISO 8510-2

-

ISO 14616

-

ISO 37

-

-

ꁇ ASTM Standard

-

ASTM D202

-

ASTM D882

-

ASTM D3078

-

ASTM D4918

-

ASTM F1140

-

ASTM F2029

-

ASTM F2054

-

ASTM D1709

-

ASTM D3420

-

ASTM D2732

-

ASTM D374

-

ASTM D1777

-

ASTM F392

-

ASTM D 2063

-

ASTM D3198

-

ASTM D3474

-

ASTM D5264

-

ASTM D5458

-

ASTM D1894

-

ASTM F2338

-

ASTM D1424

-

ASTM D689

-

ASTM F2096

-

ASTM 0000

-

ASTM D2923

-

ASTM D6828

-

ASTM D5342

-

ASTM D5650

-

ASTM D3301

-

ISO 7263-1

-

ASTM D642

-

ASTM D4169

-

ASTM D2659

-

ASTM D4577

-

ASTM D999

-

ASTM D3121

-

ASTM D1000

-

ASTM D3654

-

ASTM D1238

-

ASTM D4917

-

ASTM D3330

-

ASTM F1921

-

ASTM D1922

-

ASTM D638

-

ASTM E4

-

ASTM F904

-

ASTM F88

-

ASTM D1938

-

-

ꁇ YBB Standard

-

ꁇ QB/T Standard

-

ꁇ YY/T Standard

-

ꁇ BB Standard

-

ꁇ TAPPI Standard

-

ꁇ IEC Standard

-

ꁇ JIS Standard

-

ꁇ EN DIN Standard

-

ꁇ PSTC Standard

-

FINAT Standard

-

ꁇ BS Standard

-

ꁇ NF Standard

-