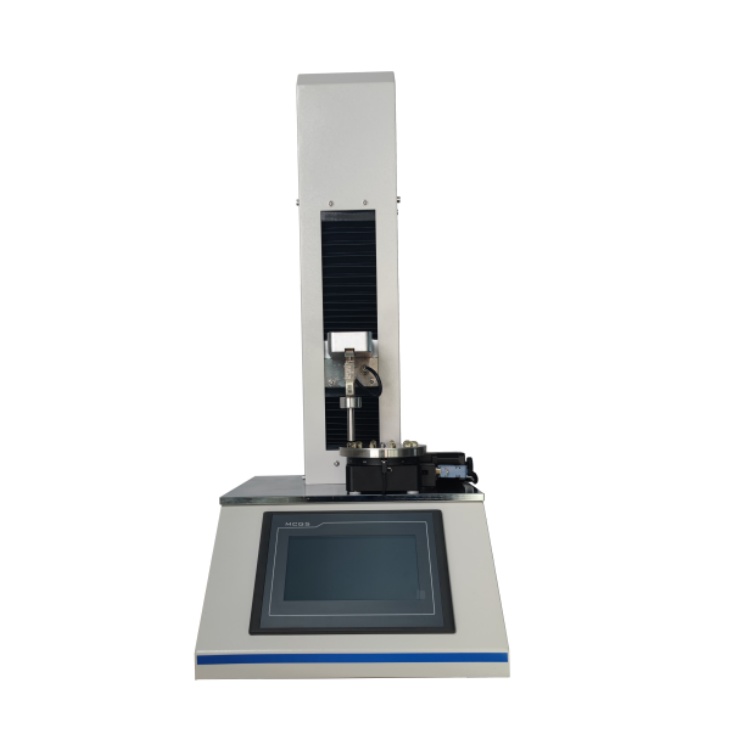

LSG-01 Aluminum-Plastic Combination Cap Opening Force Tester

Aluminum-plastic combination caps are extensively utilized across various sectors for their excellent sealing capabilities and tamper-evident features. These caps integrate the strength of aluminum with the flexibility and cost-effectiveness of plastic, making them ideal for sealing bottles containing beverages, pharmaceuticals, cosmetics, and other liquids. In the pharmaceutical sector, these caps are essential for providing robust seals, offering tamper evidence, and preserving product integrity.

Aluminum: Commonly used for the outer layer, providing a strong, tamper-evident, and aesthetically pleasing finish.

Plastic: Utilized for the inner liner or as part of the closure mechanism, ensuring a tight seal and ease of opening.

Force Tests on Aluminum-Plastic Combination Cap

The LSG-01 Aluminum-Plastic Combination Cap Opening Force Tester is capable of performing a range of critical force tests, including:

- Tab Tear-Off Force (Tab Removing Force): In compliance with ISO 8872 and ISO 10985 standards.

- Force to Pull Off Plastic Component: As per ISO 10985.

- Force to Remove Plastic Component: Conforming to ISO 8536-7 and ISO 8536-6.

- Tensile and Elongation Force for Aluminum Part: Ensures the aluminum component's durability and flexibility.

Technical Features

- Industrial-Grade PLC Control System and HMI Interface: Provides stable, accurate, and user-friendly operation.

- Compatibility with Various Accessories: Suitable for tests such as tensile, compression, breaking force, hardness, peel, opening, puncture, push-pull, and more.

- Real-Time Display of Test Results: Facilitates immediate feedback and data processing.

- Dot-Matrix Type Micro Printer: Allows long-term preservation of test results.

- Advanced Safety Features: Includes power-off parameter memory, overload protection, limit protection, and automatic return at the end of the test.

- RS232 Communication Interface and Professional Software (Optional): Enhances data management and analysis.

| Item | Parameters | |

| Test Range | 0~500N (Or as required) | |

| Stroke | 200mm (without clamp) | |

| Speed | 1~500mm/min(or as required) | |

| Displacement Accuracy | 0.01mm | |

| Accuracy | 0.5% F.S. | |

| Control | Screen, Microprinter, RS232(optional) | |

| Power | 110~220V |

The LSG-01 Aluminum-Plastic Combination Cap Opening Force Tester is highly versatile, performing a variety of essential tests in the medical packaging industry to ensure the quality and safety of packaging materials and components. These include, but are not limited to:

- Ampoule Bottle Breaking Force Test

- Infusion Bottle Cap Opening Force and Tear Tab Tear Force Tests

- Heat Seal Strength, Tensile Strength, Peel Strength, and Elongation at Break Tests: For materials such as aluminum foil, PVC rigid sheets, and composite films.

- Vial Combination Cap Opening Force, Puncture Force, and Aluminum Foil Tear Force Tests

Tensile testing of other materials, etc.

The LSG-01 adheres to several international standards, ensuring reliable and consistent test results:

- ISO 8872

- ISO 7500-1

- ISO 10985

- ISO 8362-6

- ISO 8362-7

The LSG-01 Aluminum-Plastic Combination Cap Opening Force Tester is an indispensable tool for any industry requiring precise and reliable testing of cap opening forces. By integrating state-of-the-art technology and adhering to international standards, this tester ensures your products meet the highest quality and safety requirements.

-

ꄶ By Tester Name

-

Leak Tester

-

Pressure Decay/Burst Tester

-

Micro Leak Tester

-

Gross Leak Tester

-

Tensile Tester

-

Heat Seal Tester

-

Coefficient of Friction Tester

-

Falling Dart Impact Tester

-

Falling Ball Impact Tester

-

Pendulum Impact Tester

-

Hot Tack Tester

-

Shrink Tester

-

Cling Peel Force Tester

-

Thickness Tester

-

Flex Durability Tester

-

Elmendorf Tear Tester

-

Peel Test Stand

-

Test Stand

-

Impact Tester

-

Carbonation Tester

-

Torque Tester

-

Bottle Tester

-

Lid Film Peeling Tester

-

Box Compression Tester/BCT Tester

-

Ink Rub Tester

-

Mullen Bursting Tester

-

Plybond Tester

-

Stiffness Tester

-

Folding Endurance Tester

-

Beating Freeness Tester

-

COBB Tester

-

Concora Medium Fluter

-

Puncture Tester

-

Crush Tester

-

Ink Rub Tester

-

Paper Core Compression Tester

-

Paper Dirt Tester

-

Board Thickness Tester

-

Paper Thickness Tester

-

Softness Tester

-

Short Span Compression Tester

-

Paper Tear Tester

-

Smoothness Tester

-

Air Permeance Tester

-

Paper Tensile Tester

-

Valley Beater

-

Bending Stiffness Tester

-

Taber Stiffness Tester

-

Ampoule Breaking Tester

-

Softgel Hardness Tester

-

Pharm and Medical Packaging Tester

-

Glass Grain Sampling Machine

-

Cap Opening Force Tester

-

Medical Syringe Tester

-

Puncture Tester

-

Drawing Volume Tester

-

Tablet Hardness Tester

-

Motorized Torque Tester

-

Package Compression Tester

-

Verticality Tester

-

Bottle Thickness Tester

-

Top Load Tester

-

Vibration Test Machine

-

Ball Tack Tester

-

High Speed Unwinding Force Tester

-

Loop Tack Tester

-

Tape Shear Adhesion Tester

-

Cleaning Efficacy Tester

-

Mop Cloth Coefficient of Friction Tester

-

Hot Air Thermal Shrinkage Tester

-

Mop Friction Force Tester

-

Charpy and lzod lmpact Tester

-

Melt Flow Rate Tester

-

Stylus Pen Sliding and COF Tester

-

Pendulum Hammer Striking Tester

-

Texture Analyzer

-

Gel Strength Tester

-

Tensile Tester

-

-

ꄶ By Test Type

-

ꄶ By Test Material

-

ꄶ By Industry

-

ꄶ By Test Standard

-

ꁇ GB Standard

-

GB 8808

-

GB 7000.1

-

GB 10006

-

GB 15171

-

GB/T 10792

-

GB/T 1040

-

GB/T 9639

-

GB/T 8809

-

GB/T 13519

-

GB/T 6672

-

GB/T 451

-

GB/T 6547

-

GB/T 10440

-

GB/T 18454

-

GB/T 19741

-

GB/T 17447

-

GB/T 17876

-

GB/T 10004

-

GB/T 40266

-

GB/T 2637

-

GB/T 12416.2

-

GB/T 6582

-

GB/T 15267

-

GB/T 16578.2

-

GB/T 55

-

GB/T 2423

-

GB/T 20138

-

GB/T17876

-

GB/T 8942

-

GB/T 2679.10

-

GB/T12914

-

GB/T 24328.3

-

GB/T 24328.4

-

GB/T 24328.5

-

GB/T24325

-

GB/T 2679.3

-

GB/T 22364

-

GB/T 2679.8

-

GB/T 6546

-

GB/T 6548

-

GB/T 22874

-

GB 2679.6

-

GB/T 4857.3

-

GB/T 4857.4

-

GB 4857.7

-

GB/T 4852

-

GT/T 4851

-

GB/T 3682.1

-

GB/T 3682.2

-

GB/T18742

-

-

ꁇ ISO Standard

-

ISO 8295

-

ISO 11607

-

ISO 7765

-

ISO 4593

-

ISO 3034

-

ISO 534

-

ISO 719 ISO 720

-

ISO 12625

-

ISO 6383

-

ISO 1974

-

ISO 16260

-

ISO 9895

-

ISO 1924-1

-

ISO 1924-2

-

ISO 1924-3

-

ISO 12625-4

-

ISO 12625-5

-

ISO 5264

-

ISO 2493-2

-

ISO 12192

-

ISO 3037

-

ISO 3035

-

ISO 16945

-

ISO 2234

-

ISO 12048

-

ISO 2874

-

ISO 2872

-

ISO 8113

-

ISO 2247

-

ISO 1133-2

-

ISO 1133-1

-

ISO 8510-2

-

ISO 14616

-

ISO 37

-

-

ꁇ ASTM Standard

-

ASTM D202

-

ASTM D882

-

ASTM D3078

-

ASTM D4918

-

ASTM F1140

-

ASTM F2029

-

ASTM F2054

-

ASTM D1709

-

ASTM D3420

-

ASTM D2732

-

ASTM D374

-

ASTM D1777

-

ASTM F392

-

ASTM D 2063

-

ASTM D3198

-

ASTM D3474

-

ASTM D5264

-

ASTM D5458

-

ASTM D1894

-

ASTM F2338

-

ASTM D1424

-

ASTM D689

-

ASTM F2096

-

ASTM 0000

-

ASTM D2923

-

ASTM D6828

-

ASTM D5342

-

ASTM D5650

-

ASTM D3301

-

ISO 7263-1

-

ASTM D642

-

ASTM D4169

-

ASTM D2659

-

ASTM D4577

-

ASTM D999

-

ASTM D3121

-

ASTM D1000

-

ASTM D3654

-

ASTM D1238

-

ASTM D4917

-

ASTM D3330

-

ASTM F1921

-

ASTM D1922

-

ASTM D638

-

ASTM E4

-

ASTM F904

-

ASTM F88

-

ASTM D1938

-

-

ꁇ YBB Standard

-

ꁇ QB/T Standard

-

ꁇ YY/T Standard

-

ꁇ BB Standard

-

ꁇ TAPPI Standard

-

ꁇ IEC Standard

-

ꁇ JIS Standard

-

ꁇ EN DIN Standard

-

ꁇ PSTC Standard

-

FINAT Standard

-

ꁇ BS Standard

-

ꁇ NF Standard

-